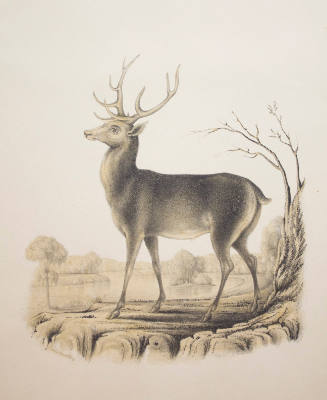

"Athens" Platter

Maker

W. Adams & Sons

(English)

Date1849

MediumEarthenware; transferprinted

DimensionsOverall: 15 1/2 x 12in. (39.4 x 30.5cm)

ClassificationsFURNISHINGS

Credit LineGift of Col. Edna Stappenbeck in memory of her Grandmother, Amelia K. Voll

Terms

Object number96.27

DescriptionEight-sided platter with black transfer-printed decoration. Center image depicts classical buildings, pond, fountain, trees and two swans. Border of foliate pattern and classical buildings.On View

Not on viewCollections

Copyright<a rel="license" href="http://creativecommons.org/licenses/by-nc/4.0/"><img alt="Creative Commons License" style="border-width:0" src="https://i.creativecommons.org/l/by-nc/4.0/80x15.png" /></a><br />This work is licensed under a <a rel="license" href="http://creativecommons.org/licenses/by-nc/4.0/">Creative Commons Attribution-NonCommercial 4.0 International License</a>.

Label TextTransfer printing onto earthenware developed in the late eighteenth century in the Staffordshire region of England, an area rich in clay and coal deposits. Commonly referred to Flow Blue or Staffordshire, the ornamentation was an attempt to inexpensively replicate Chinese export porcelain painted with blue and white decoration. English potters catered to their American clientele through their choice of ornament—American urban and pastoral scenes. Many of the views were based on Nathaniel Willis’s album American Scenery, which features engravings after the artist Henry Bartlett.

At the turn of the nineteenth century, the pottery industry in Staffordshire, England, was revolutionized by the development of the transfer printing process. It enabled potters to create embellished earthenware for a middle class market in an economical and efficient manner.

Transfer printing is a process wherein a copper plate is engraved with a pattern then rubbed with color and printers’ oil, heated, and applied to a sheet of transfer paper. The paper is pressed to the earthenware object, rubbed with a special brush, and then left to set before immersion in cold water to release the paper, leaving the design on the ceramic. Lastly, the article is fired, glazed, and refired to make the surface and pattern durable and impervious to moisture.

Bold, flowing designs, which masks flaws in the earthenware clay, characterize transfer-printed ceramics. The blue color was, at first, one of the few capable of withstanding the high heat of the kilns. By the 1840s other colors including green, brown, and red were introduced.